Oxygen generators for gold and silver mining

Oxygen application

OXYMAT On-site Oxygen for Mining and Mineral Processing

Boost gold mining efficiency and recovery with OXYMAT’s oxygen generators, crucial for cyanide leaching operations. . Our systems provide high-purity oxygen that enhances leaching efficiency, reduces cyanide usage, and cuts operational costs. Designed for rugged conditions, they are perfect for both harsh and remote mining operations. Key advantages include:

- Maximized Gold Recovery: Optimizes oxygen levels for more efficient cyanide leaching.

- Cost Savings: Reduces cyanide consumption and external oxygen supply costs.

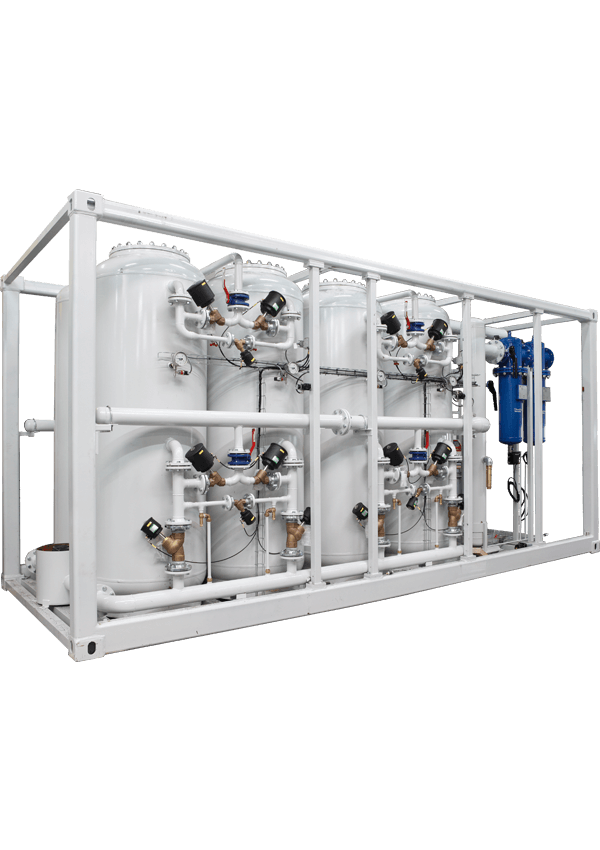

- In-frame Solutions: Space-saving, easy-to-integrate designs. Learn more here.

- Continuous Oxygen Supply: Reliable performance in harsh, remote environments.

- Eco-Friendly: Minimizes carbon footprint with on-site oxygen production.

- Scalable Systems: Adaptable to different mining needs.

Leaching

In silver and gold mining extraction, oxygen is one of the key elements used for ore processing as pressure oxidation and cyanidation. With oxygen generators you will significantly increases gold recovery and ore throughput. Furthermore, it reduces cyanide cost and waste products.

Quick start-up

Our units are offered in a well proven plug-and-play solution. This means installation and start-up can be carried out in a couple of days. We have units working in more than 50 mines around the globe.

Green solution

Oxygen reduces the use of cyanide and other waste products in the leaching process. Our oxygen generators have the absolute lowest power consumption on the market – 0.55 kW/kg oxygen. This also means we have the lowest CO2 emission of any O2 generator.

Special design features

- Capacity ranges up to 50 TPD oxygen

- Low power consumption 0.55 kW/kg Oxygen

- Low CO2 emission

- Designed for durability in rough conditions

- Quick on-site installation and start-up

- Optional container or frame-built solution

- Remote control access

Advantages of OXYMAT oxygen generators

Advantages of OXYMAT oxygen generators

- Increased gold recovery – higher dissolved oxygen level in leaching process enhances the gold cyanidation, thus increasing gold extraction rate significantly.

- Decreased retention time by leaching – conventional leaching time of 96/72 hrs can be reduced by up to 50 %.

- Increased ore throughput

- Increased silver recovery – silver is being dissolved in the leaching process in the same process reaction as gold.

- Decreased cyanide consumption – the sufficient level of oxygen reduces the amount of cyanide required.

- Decreased waste treatment – the reduction in the amount of cyanide needed in the leaching process also decreases the amount of cyanide that must be removed from the waste stream. The oxygen generated can be used as a feed gas to an ozone generator and injected directly into the waste stream as an environmentally friendly oxidizing agent.

Quality

To learn more about our approach to quality, please visit our quality page.

To learn more about our approach to quality, please visit our quality page.