Oxygen for glass production

Oxygen application

OXYMAT oxygen generators improve efficiency and lower costs in glass production. They allow furnaces to reach higher temperatures faster, which speeds up the melting process and enhances the quality of the glass. This technology offers a practical way to streamline operations and cut energy consumption.

OXYMAT oxygen generators improve efficiency and lower costs in glass production. They allow furnaces to reach higher temperatures faster, which speeds up the melting process and enhances the quality of the glass. Our technology offers a practical way to streamline operations and cut energy consumption.

Glass blowing

Oxygen generators enhance glass blowing by providing a purer oxygen supply, allowing for higher furnace temperatures. This increases control over the molten glass, improves working speed, and helps achieve finer details in the glasswork. The clean burn from pure oxygen also reduces impurities that could affect the glass's quality.

Boost your glass production

For facilities that run multiple production lines with different oxygen needs, our generators can be adjusted in output and match specific line requirements easily. With our oxygen generators you will increase furnace efficiency, eliminate impurities, and achieve precise glass shaping. Upgrade to a cleaner, faster production process.

Quick ROI (1-2 years)

Power consumption is more than 40% lower than any other oxygen generator on the market. Overall cost reduction up to 80% in comparison with cylinders. No on-going costs (refills, delivery and transportation charges etc.)

Applications include

Applications include

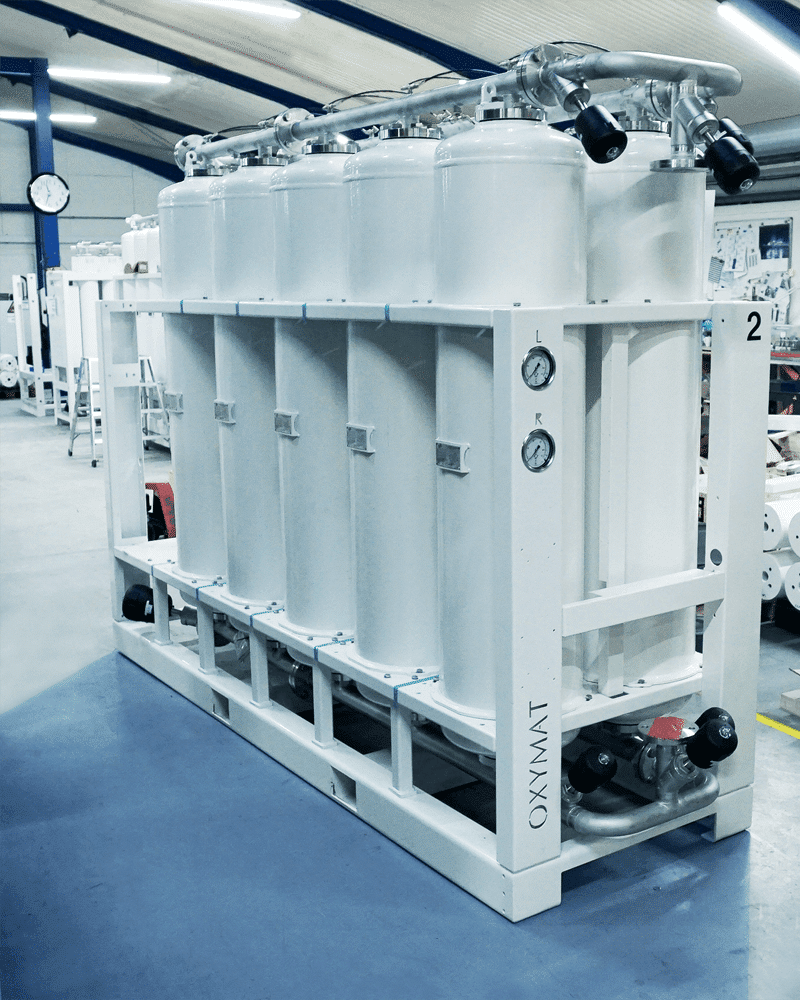

- Our models range from 2.4 to 576.42 kg/h

- Modular design that can be upscaled if capacity need change

- All pressure vessels are sandblasted and powder coated P265 in C4 grade for extended lifetime and reduced maintenance

- Our models range from 2.4 to 576.42 kg/h

- Modular design that can be upscaled if capacity need change

- All pressure vessels are sandblasted and powder coated P265 in C4 grade for extended lifetime and reduced maintenance

Advantages of OXYMAT oxygen generators

Advantages of OXYMAT oxygen generators

- No safety risks of handling high-pressure cylinders

- Safe delivery; controlled flow and uninterrupted gas

- Easily installed in addition to any existing oxygen supply (cylinders, cryogenic or other PSA systems)

- Generate the O2 you need, when and where you need it

- Very low OPEX compared to cylinders or liquid gas

- Easy scalable oxygen supply

- No need to rely on external gas suppliers and fluctuating prices

- Advanced central control system carefully operates the system ensuring the desired oxygen quantity and quality is supplied

- Operational in extreme temperatures

- No safety risks of handling high-pressure cylinders

- Safe delivery; controlled flow and uninterrupted gas

- Easily installed in addition to any existing oxygen supply (cylinders, cryogenic or other PSA systems)

- Generate the O2 you need, when and where you need it

- Very low OPEX compared to cylinders or liquid gas

- Easy scalable oxygen supply

- No need to rely on external gas suppliers and fluctuating prices

- Advanced central control system carefully operates the system ensuring the desired oxygen quantity and quality is supplied

- Operational in extreme temperatures

Quality

To learn more about our approach to quality, please visit our quality page

To learn more about our approach to quality, please visit our quality page