Pulp and paper production with oxygen generators

Oxygen application

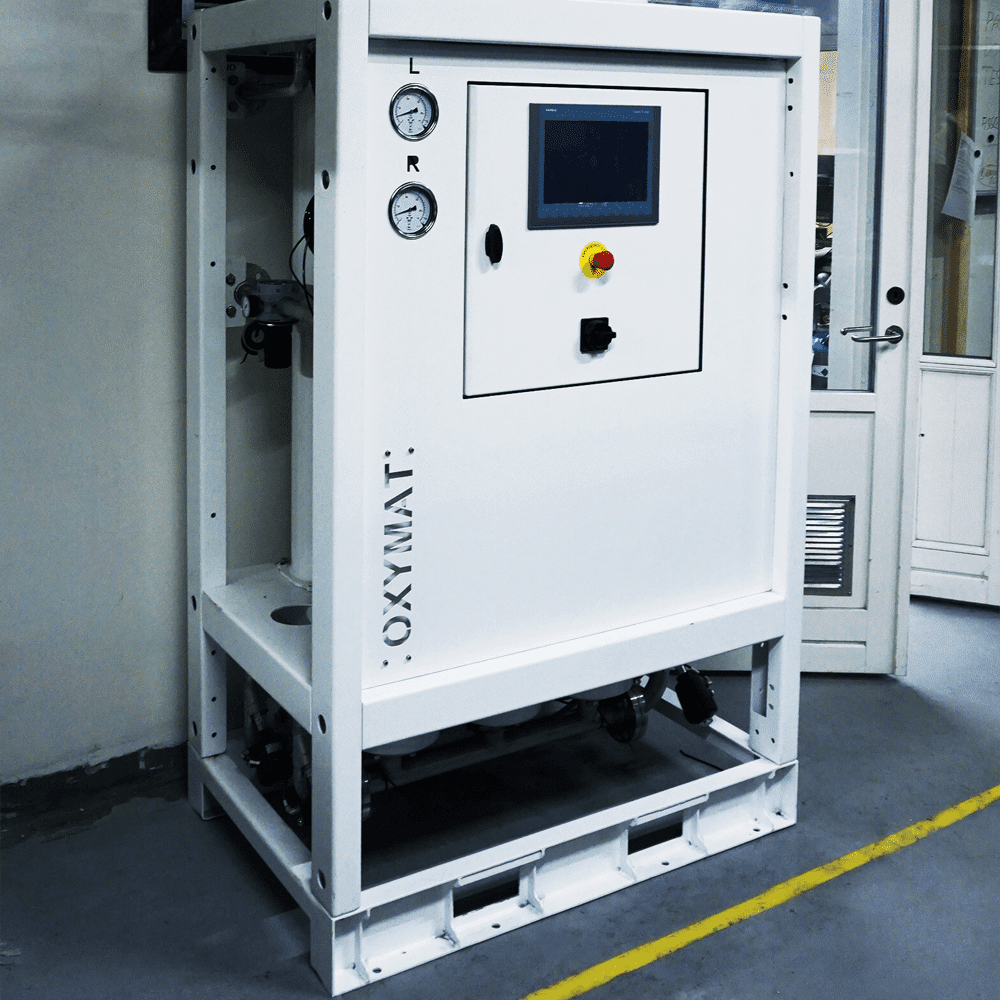

OXYMAT on-site oxygen for pulp and paper production

OXYMAT’s oxygen systems increase efficiency and sustainability in pulp and paper production, supporting processes such as bleaching, delignification, and de-inking. By delivering high-purity oxygen, our systems enhance production quality, reduce chemical usage, and improve operational costs. Key advantages include:

- Efficient bleaching and delignification: Minimizes the need for harmful chemicals.

- Enhanced de-inking: Improves recycling for higher-quality paper.

- Cost savings: Lowers reliance on external oxygen supplies.

- Wastewater treatment: Optimizes biological treatment.

- Reduced emissions: Lowers CO2 and other harmful emissions.

- Scalable solutions: Adaptable to various plant sizes.

Bleaching and Delignification

Oxygen plays a crucial role in both the bleaching process and delignification, replacing chlorine and chlorine dioxide, which results in reduced environmental impact and improved safety. Oxygen delignification can remove 40-50% of the residual lignin in non-bleached pulp, significantly reducing the need for harsh chemicals and lowering operating costs.

De-inking

The de-inking process, crucial for recycling paper, benefits from oxygen's ability to improve the flotation process, ensuring higher quality recycled paper. With OXYMAT oxygen generators, the efficiency of the de-inking process can be improved by significantly, resulting in better separation of ink from the paper fibers and higher quality recycled paper.

Wastewater Treatment

Oxygen is vital for the biological treatment of wastewater in the pulp and paper industry. The treatment process breaks down organic matter present in the wastewater, enhancing water quality before discharge. OXYMAT’s on-site oxygen generators provide a continuous and reliable supply of oxygen, increasing the efficiency of wastewater treatment by up to 30%. This helps industries comply with stringent environmental regulations.

Advantages of OXYMAT oxygen generators

Advantages of OXYMAT oxygen generators

- Cost-Effective: Significantly reduce costs compared to traditional oxygen supply methods.

- Energy Efficient: Our systems are designed to consume less energy, optimizing operational efficiency.

- Reliability: Continuous and on-demand oxygen supply without dependency on external suppliers.

- Environmental Benefits: Reduce harmful emissions and chemical use, contributing to a cleaner and safer environment.

Why Choose Oxymat?

OXYMAT’s oxygen generators are renowned for their durability, low maintenance, and adaptability to various industrial needs. By integrating our solutions, a pulp and paper factory can achieve enhanced productivity, reduced operational costs, and a smaller carbon footprint.

Quality

To learn more about our approach to quality, please visit our quality page.

To learn more about our approach to quality, please visit our quality page.