Table of Contents

- Why oxygen matters in biogas production

- Oxygen-based desulfurization: a proven method

- Why on-site oxygen generation is the smart choice

- Field proven in real-world plants – OXYMAT oxygen generators

- FAQ

The production of biogas has rapidly gained traction as a sustainable method for converting organic waste into usable energy. From agricultural manure and municipal waste to byproducts from food industries, the feedstocks are abundant and renewable. Today, many plants operate in decentralized locations, with biogas either injected into the natural gas grid or used directly in combined heat and power (CHP) engines to generate electricity and heat.

But optimizing biogas for energy use requires more than just anaerobic digestio, it demands gas treatment, and this is where oxygen plays a decisive role,

Why oxygen matters in biogas production

In its raw form, biogas contains not only methane but also undesirable compounds like carbon dioxide and hydrogen sulfide (H₂S). When biogas is burned in CHP gas engines, the H₂S is oxidized to form sulfur dioxide (SO₂), a highly corrosive gas that damages engine components, heat exchangers, and piping infrastructure.

To protect critical equipment, removal of H₂S before combustion is non-negotiable.

Oxygen-based desulfurization: a proven method

One of the most efficient methods for reducing hydrogen sulfide levels is oxygen injection directly into the biogas fermenter. When gaseous oxygen is introduced into the headspace above the slurry, naturally occurring microorganisms oxidize the H₂S into elemental sulfur:

2 H₂S + O₂ → 2 S + 2 H₂O

The sulfur is then deposited on internal surfaces and eventually returns to the liquid phase, where part of it is flushed out with the digested biomass.

This biological process is simple, robust, and does not require chemicals or complex scrubbing units, but it relies entirely on a stable oxygen supply.

Why on-site oxygen generation is the smart choice

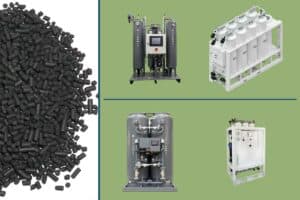

OXYMAT’s PSA oxygen generators are increasingly being integrated into biogas plants across Northern Europe for one key reason: they guarantee a continuous, cost-effective supply of oxygen, on demand.

Here’s what makes them indispensable in biogas applications:

- Reliability: Unlike cylinder deliveries or liquid oxygen tanks, OXYMAT systems produce oxygen on-site, ensuring uninterrupted supply regardless of logistics.

- Cost-efficiency: The cost per Nm³ is significantly lower over time compared to purchasing oxygen externally.

- Process fit: The desulfurization process does not require ultra-high purity. Our PSA generators deliver oxygen at 93–95% purity, ideal for this application.

- Scalability: Oxygen demand in biogas plants often starts at 10 Nm³/hour and grows. OXYMAT units are modular, allowing easy capacity upgrades.

- Compact footprint: Our generators are available as standalone systems or in containerized plug & play formats, simplifying installation and relocation.

Field proven in real-world plants – OXYMAT oxygen generators

OXYMAT has supplied PSA oxygen generators to a wide range of biogas installations, particularly in Denmark, Germany, and the Netherlands. These systems are trusted by operators who need high uptime, minimal maintenance, and a long lifecycle.

With no reliance on external delivery schedules or fluctuating supply costs, on-site oxygen generation gives plant operators full control over a key part of their process—one that directly impacts equipment lifespan and operational cost

Simplify your operations. Generate your oxygen on site.

Contact us to explore how OXYMAT oxygen generators can be integrated into your biogas plant.

FAQ

Oxygen is used in the biogas production process to remove hydrogen sulfide (H2S) from the biogas. H2S is an unwanted component in biogas, as it can lead to equipment corrosion and damage.

A simple and effective method to remove hydrogen sulfide is by introducing gaseous oxygen into the biogas fermenter. Oxygen reacts with hydrogen sulfide, leading to its oxidation into elemental sulfur by microorganisms.

The chemical reaction is as follows: 2 H2S + O2 -> 2 S + 2 H2O. This reaction converts hydrogen sulfide into elemental sulfur and water.

The sulfur accumulates on the surfaces inside the biogas fermenter and eventually reenters the liquid biomass. Some of it may be converted back into hydrogen sulfide and flushed out with the degassed slurry.

Onsite oxygen generation is preferred because it offers a reliable and cost-effective solution for providing the required amount of oxygen in biogas plants. It eliminates the need for external oxygen supplies and ensures a continuous oxygen source.

Oxygen consumption in biogas plants typically starts at flow rates of 10 Nm3/hour and increases as needed for the desulfurization process.

The desulfurization process is not highly sensitive to gas purity. Oxygen purities ranging from 93% to 95% pure oxygen are suitable for effective removal of hydrogen sulfide.