Table of contents

- Most common disinfection methods used in the wastewater treatment

- How oxygen generators support ozone production?

- On-site oxygen generators: a reliable ozone source

- OXYMAT’s PSA oxygen generators powering ozone disinfection

- FAQ

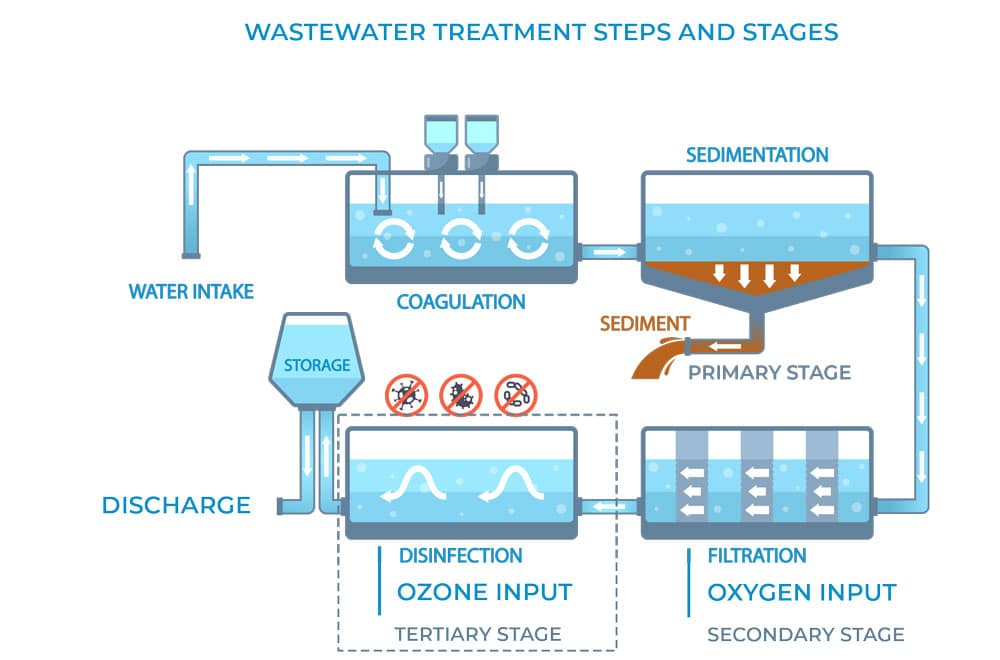

After the secondary stage of wastewater treatment, starts the tertiary stage, also known as advanced treatment of water, which is the final phase of the wastewater purification. Here water gets further purified by removing any remaining contaminants and impurities to meet specific quality standards before it is discharged back into the environment or reused. To achieve the desired purification in tertiary stage, wastewater treatment plants can apply several methods of water purification. They include additional filtration, disinfection, advanced oxidation processes, adsorption, and reverse osmosis. These methods are applied in combination or separately. The specific sequence and combination of these methods can vary based on discharged water quality requirements and regulatory guidelines.

Of all applied methods disinfection is of great importance, as it acts as the primary means for destruction of pathogens and microorganisms. It prevents the spread of waterborne diseases which int turns maintains public health and the environment.

Most common disinfection methods used in the wastewater treatment

Contemporary methods of disinfection include chlorination, UV disinfection, ozonation, and chloramines. They can either be employed as combination or separately. It all depends on the needed purity requirements. The highlights below provide a brief overview of these methods and how they work.

Comparing disinfection technologies

Chlorination: Chlorine is effective in destroying a wide range of bacteria, viruses, and other pathogens that can cause waterborne diseases. The process works by chemically reacting with the cell walls or genetic material of microorganisms, disrupting their function, and preventing their growth.

Chloramines: involves the use of chloramines formed by combining chlorine with ammonia, is used as a secondary disinfectant to provide a residual disinfectant effect throughout the distribution system. It offers longer-lasting disinfection compared to chlorination.

UV Disinfection: It involves exposing the water to ultraviolet (UV) light, which damages the genetic material of microorganisms, making them unable to replicate and causing their destruction.

Ozonation: Ozone disinfection is commonly employed for its strong oxidizing properties and ability to effectively kill microorganisms. It is especially effective in removing taste, odor, and color-causing compounds from water. Ozone is often used in conjunction with other disinfection methods to achieve higher level treatment.

As previously mentioned, all disinfection methods can either be employed in combination or separately. While chlorination is cheap and cost effective it still raises concerns in terms of odor and taste of the discharged water. UV radiation is effective on killing microorganisms, its environmentally friendly and leaves no residual taste or odor, however, UV method requires continues electricity, is less effective in turbid water, and has no residual disinfection properties. Similarly, chloramines method raises concern in terms of disinfection byproducts, therefore careful control of ammonia and chlorine ratios are necessary. Ozonation on the other hand is considered as a powerful disinfectant, it leaves no residual taste or odor and leaves no disinfection byproducts.

Benefits of using ozone over other disinfection methods

Furthermore, Ozone is considered more effective than chlorine in destroying viruses and bacteria. After ozonation there is no regrowth of harmful microorganisms. In addition, ozonation increases the level of oxygen in the receiving stream and can eliminate the need for reaeration. The method requires only short water-contact time, approximately 10 to 30 minutes (ref.: WASTEWATER TECHNOLOGY FACT SHEET, OZONE DISINFECTION). Overall, whether going for ozonation alone or in combination with the above-mentioned methods, applying ozone is essential for additional purification in tertiary stage.

How oxygen generators support ozone production?

In wastewater treatment plants, ozone is usually produced on-site using a multi-step process. To ensure a consistent and reliable supply of ozone, many plants employ technologies like on-site oxygen gas generator with pressure swing adsorption (PSA) technology to generate high-purity oxygen gas from the air, also known as industrial oxygen.

The generated oxygen gas is then directed into the ozone generation system which is equipped with electrodes and a dielectric material. Inside the ozone generator, a high voltage is applied to the electrodes, creating a strong electric field that initiates corona discharge. The results of the corona discharge are reaction of oxygen atoms with other oxygen molecules in the gas stream, resulting in the formation of ozone. The energy provided by corona discharge enables the conversion of stable oxygen molecules into ozone molecules.

Once produced, the ozone is injected into the wastewater treatment process. It will either be applied as a disinfectant alone or as an addition to other disinfection methods. Alone or as an additional disinfectant, ozone´s powerful oxidative properties help break down remaining organic compounds, eliminate pathogens, and improve overall water quality.

On-site oxygen generators: a reliable ozone source

Utilizing on-site oxygen gas generators for ozone production, wastewater treatment plants can ensure a self-sufficient and continuous supply of ozone, which eliminates the need for storing or transporting ozone gas, making the process more efficient and cost-effective.

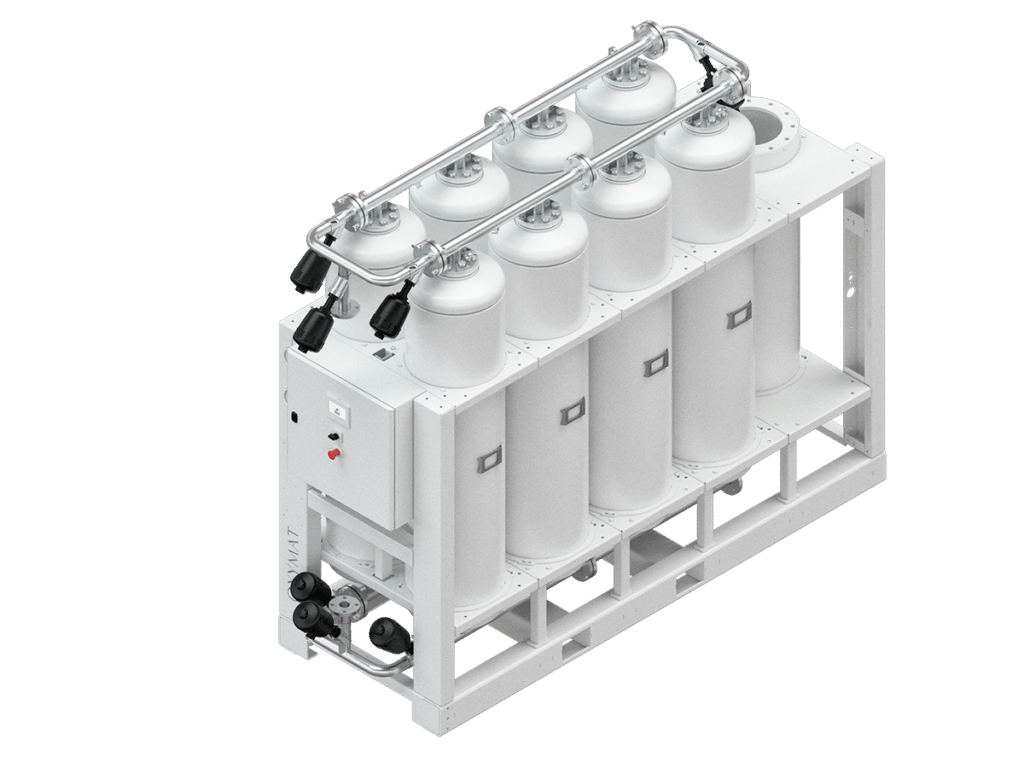

A reliable oxygen gas generator provider and a major player in the market is OXYMAT. Oxygen gas generators produced by OXYMAT are of PSA Technology. They come in various capacity output and physical footprint and can either be applied in modular settings or as a stand-alone generator.

OXYMAT’s PSA oxygen generators powering ozone disinfection

According to Freshwater Information System Europe (WISE FRESHWATER), Denmark with its more than 330 water plants treats more than 99% of its urban wastewater. Located in Denmark, OXYMAT with their PSA oxygen gas generators have contributed to achieving this result. OXYMAT generators are in operation around the country and have been in service for more than three decades. Their generators are used both in secondary, for oxygen generation, and at the tertiary stage for ozone.

Learn more about OXYMAT’s PSA Oxygen Gas Generators here.

The tertiary stage of wastewater treatment plays a vital role in achieving high-quality water purification. In this stage, the aforementioned disinfection methods are essential for eliminating remaining pathogens and microorganisms, such as viruses and bacteria. Ozone, generated through on-site oxygen gas generators like those provided from OXYMAT, offer powerful means in effectively removing contaminants.

As a disinfectant, ozone can either be applied alone or in combination with other methods. In Denmark, OXYMAT has been a trusted provider of oxygen generation PSA technology for more than three decades. Both with ozone and oxygen, their generators have contributed to the successful treatment of wastewater in numerous plants across the country. Overall, by generating ozone on-site, wastewater treatment plants ensure a continuous and self-sufficient supply of ozone, leading to improved efficiency, cost-effectiveness, and environmental sustainability in the purification process.

FAQ

The tertiary stage is the final phase of wastewater purification. It’s crucial for further purifying water by removing remaining contaminants and impurities to meet specific quality standards before discharge or reuse.

Various water purification methods that are applied in the tertiary stage include additional filtration, disinfection, advanced oxidation processes, adsorption, and reverse osmosis. The selection depends on water quality requirements and regulatory guidelines.

Disinfection is important in wastewater treatment as it’s the primary means of destroying pathogens and microorganisms. It prevents the spread of waterborne diseases and safeguards public health and the environment.

There are several disinfection methods which include chlorination, UV disinfection, ozonation, and chloramines. These methods can be used individually or in combination.

Ozone is a powerful disinfectant that effectively kills microorganisms and removes taste, odor, and color-causing compounds from water. It leaves no residual taste or odor and has no disinfection byproducts.

Ozone is typically produced on-site using a multi-step process. High purity oxygen gas, generated from the air using technologies like on-site oxygen gas generators with pressure swing adsorption (PSA), is subjected to corona discharge in an ozone generator, resulting in the formation of ozone.

On-site oxygen gas generators secure a consistent and reliable supply of ozone without the need for storing or transporting ozone gas. This enhances efficiency, reduces costs, and supports continuous wastewater treatment.