Table of Contents

- Quality of CMS and why matters for PSA nitrogen generators

- Development of CMS

- How CMS Works in PSA Generators

- Benefits of CMS in Nitrogen Generators

- Applications of CMS-Based PSA Nitrogen Generators

- OXYMAT PSA Nitrogen Generators

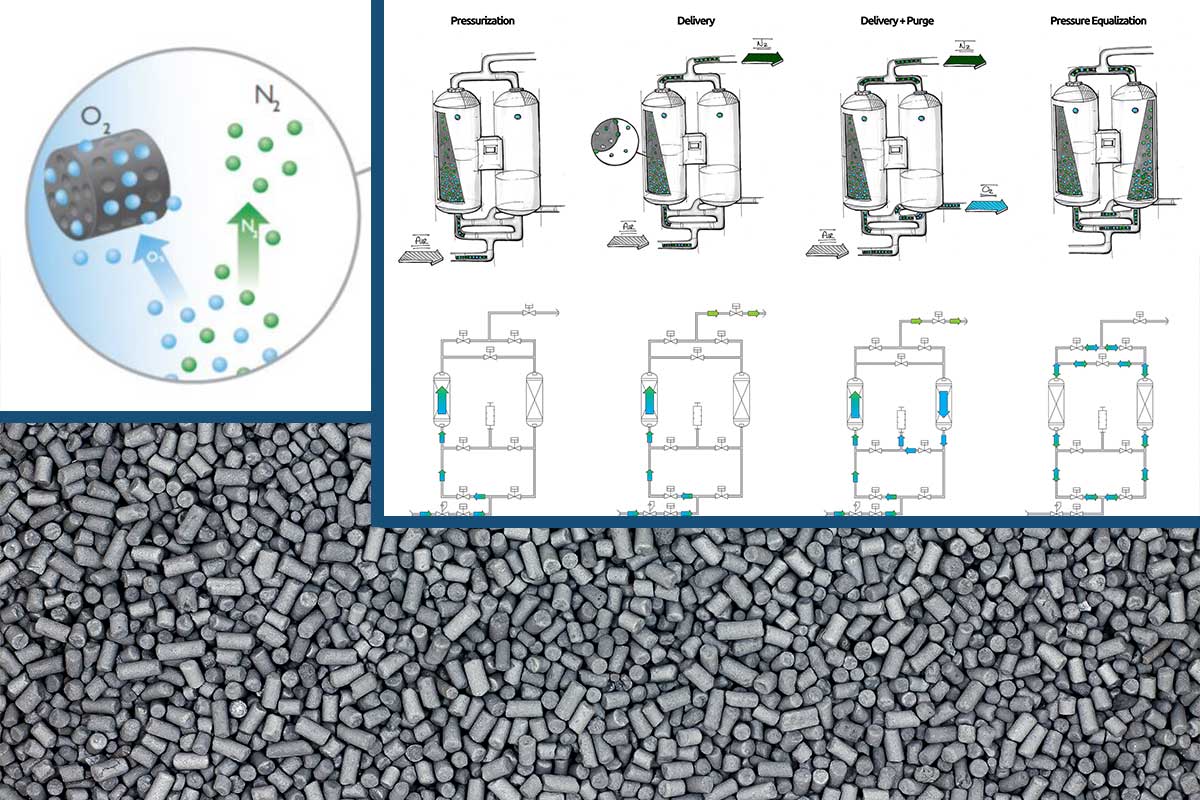

Pressure Swing Adsorption (PSA) nitrogen generators rely on Carbon Molecular Sieve (CMS) for efficient nitrogen separation. Unlike zeolite, which is used for oxygen production, CMS’s microporous structure selectively adsorbs oxygen while allowing nitrogen to pass, achieving purities of up to 99.9999%.

Quality of CMS and why matters for PSA nitrogen generators

Carbon Molecular Sieves are typically derived from two primary sources: coal and coconut shells. Both types are carbonized and activated to create the microporous structure necessary for effective gas separation. Coconut shell-based CMS, in particular, offers some advantages due to its renewable nature and harder structure, which makes it more durable. This durability is especially beneficial in PSA nitrogen generators, where the material undergoes repeated cycles of pressurization and depressurization. OXYMAT’s use of high-quality CMS ensures long-term reliability and efficiency.

Development of CMS

CMS emerged from advancements in material science during the mid-20th century. Researchers aimed to improve the performance of activated carbon for gas separation. By enhancing the pore structure, they developed CMS, ideal for the selective adsorption of oxygen in nitrogen separation processes.

How CMS Works in PSA Generators

Compressed air enters the PSA system, where CMS adsorbs oxygen molecules. The nitrogen then flows through as a product gas. During depressurization, the CMS regenerates by releasing the trapped oxygen, ready for reuse in the next cycle.

Benefits of CMS in Nitrogen Generators

CMS offers several advantages that make it indispensable in PSA nitrogen generation. Its highly efficient adsorption and regeneration cycles ensure optimal nitrogen production with minimal energy consumption. The robust structure of CMS enables it to perform consistently over long periods, reducing maintenance requirements and extending the operational life of nitrogen generators. This reliability ensures a stable, high-purity nitrogen supply, even under demanding industrial conditions.

Key benefits include:

- High Nitrogen Purity: Achieving purities of up to 99.9999%.

- Selective Adsorption: Optimized for oxygen separation from nitrogen.

- Durability and Reusability: Can endure multiple pressurization cycles without losing effectiveness.

- Energy Efficiency: Minimizes energy consumption during operation.

- Low Maintenance: Reduced need for maintenance over time due to its long-lasting performance.

Applications of CMS-Based PSA Nitrogen Generators

CMS-based PSA nitrogen generators are critical across many industries that require consistent, high-purity nitrogen supply for various applications. From preserving food quality to providing inert atmospheres in specialized environments, nitrogen plays an essential role in many sectors.

These industries include:

- Food Packaging: Nitrogen helps preserve food by displacing oxygen and slowing oxidation.

- Electronics Manufacturing: Nitrogen provides an inert environment to prevent oxidation and contamination.

- Chemical Processing: Nitrogen prevents unwanted reactions with oxygen in sensitive chemical processes.

- Marine Inerting: Nitrogen creates safe, non-flammable environments on ships.

- Pharmaceutical Manufacturing: Nitrogen ensures safe and stable conditions for drug production and packaging.

- Laser Cutting: Nitrogen prevents oxidation during precision cutting of metals and plastics.

- Beverage Industry: Nitrogen is used in the bottling process to prevent oxidation and preserve quality.

- Oil and Gas: Nitrogen prevents explosive conditions during oil extraction and processing.

- Metallurgy: Nitrogen is utilized in annealing and sintering processes to maintain controlled environments.

OXYMAT PSA Nitrogen Generators

OXYMAT’s PSA nitrogen generators, equipped with premium CMS, provide efficient, scalable solutions tailored to the needs of a wide variety of industries. Our systems are designed for energy efficiency and long-term reliability, reducing operational costs and minimizing reliance on external nitrogen supplies.

Learn more about OXYMAT nitrogen generators here.

The development of Carbon Molecular Sieve has revolutionized PSA nitrogen generation by enabling selective oxygen adsorption and ensuring high-purity nitrogen production. OXYMAT’s PSA nitrogen generators, utilizing high-quality CMS, offer reliable, cost-effective solutions for industries requiring on-site nitrogen generation, supporting processes across sectors like food packaging, electronics, pharmaceuticals, and beyond.